This year I gave the business a present, a new Millermactic 211 Mig Welder and Hypertherme 30 Plasma Cutter. We purchased the steel welding and cutting equipment to allow us to build bigger, stronger signs. Most of the time the steel will be used to build Interior frameworks to our signs allowing them to be bigger, thicker, heavier and stronger. It would also be fun to make some decorative signs and hangers as well.

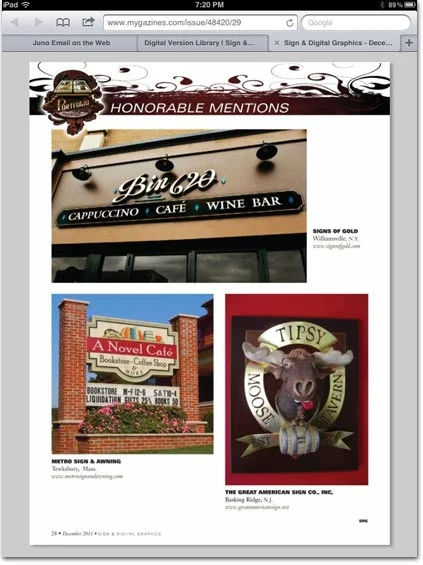

Tipsy Wins Top Honors from Sign & Digital Graphics Magazine

Tipsy Moose Tavern received an honorable mention in S&DG’s Annual Portfolio Design Contest. First place went to a good friend of ours, Roger Cox from House of Signs in Frisco Co. Congratulations Roger. A photo of Tipsy will be featured in the December edition of the magazine.

Forming the Tree

The next stage in forming the tree is to bend rings of different diameters and weld them onto the square tube skeleton.

Community Garden Concrete Tree Post

Today we will be working on the Concrete tree post for the Community Garden Project. We created a rough paper pattern for the tree, cut and welded up a steel frame structure.

Practice, Practice, Practice

This week, we are practicing our skills at concrete sculpting, all in preparation for the 2nd stage in our exciting project for Clarence Dillon Library Community Garden.

Rather that giving them an ordinary white post, we have decided to step it up and give them a tree sculpted out of concrete. Not only will this be an awesome addition to our original plans, but it will give us a chance to break out the mig welder and explore the possibilities of concrete sculpting in sign work.

To firm up our skills before working on the tree we will sharpen our skill on a few practice boards and a new faux stone skirt to the shops showroom bay window.